12 Jan Cofferdam Reusability And Repairability

When working in or near water you cannot always see or feel what may lie beneath the surface. There sometimes can be an element of surprise weather it may be a sharp rock, broken glass or re-rod you never can be 100 % sure you have a debris free work-site. The DT Cofferdam is constructed using a high strength 30 oz vinyl fabric that can withstand the elements, always take the extra step by checking your work site best as possible or even laying a geotextile fabric liner down first before installing the water inflated cofferdam.

Because of our high strength vinyl material the cofferdam can be used time and time again from one job to another. When normal wear and tear takes a toll on the cofferdam or a foreign object causes damage you can simply fix it on site and get the cofferdam back in use. This is one of many reasons the DT Cofferdam differs from the competition.

In field Repairs

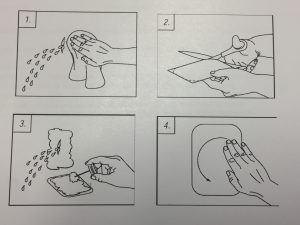

Every order is sent out with a repair kit in the event that something has caused damage during the install. In situations that a small hole is found when the cofferdam is fully inflated with water there is no need worry this can be repaired when wet in just 4 easy steps. (see below)

1 ) Clean surface of DT Dam with a clean towel or a solvent

1 ) Clean surface of DT Dam with a clean towel or a solvent

2 ) Cut appropriate size vinyl patch and round corners

3 ) Generously apply HH66 vinyl adhesive to both cofferdam surface and patch. Allow a few minutes for glue to dry. The drying process is complete when the glue exhibits a frosty color and is tacky to the touch.

4 ) Apply patch material rubbing into place continually for 1 minute

Dry Repairs

When not in use damages can be found by visually inspecting the surface and heavy wear areas or by pumping air into the cofferdam and then inspecting. The same vinyl adhesive repair technique can be used as explained above. Another option is to use a heat gun, this will melt the vinyl from the DT Dam to the appropriate sized vinyl patch insuring a water tight seal. By setting the heat gun to the proper heat setting (do test patches before trying this) place the patch over the damaged area place nozzle of heat gun between the patch and dam then begin using the roller with downward pressure until a seal is made. Let this cool for a few minutes then pick at the patch to observe any unsealed areas, if any are found repeat steps above.

*NOTE : IF ANY DAMAGES ARE QUESTIONABLE A DETROIT TARP COFFERDAM REPRESENTATIVE SHOULD BE NOTIFIED

All DT Dams can be sent back to the manufacturing facility for annual inspections and repairs. Call us at (800) 457-5054 to arrange for your cofferdams to be repaired and inspected. We strive to keep everyone safe and take pride in providing a quality cost effective product. https://detroittarp.com

No Comments